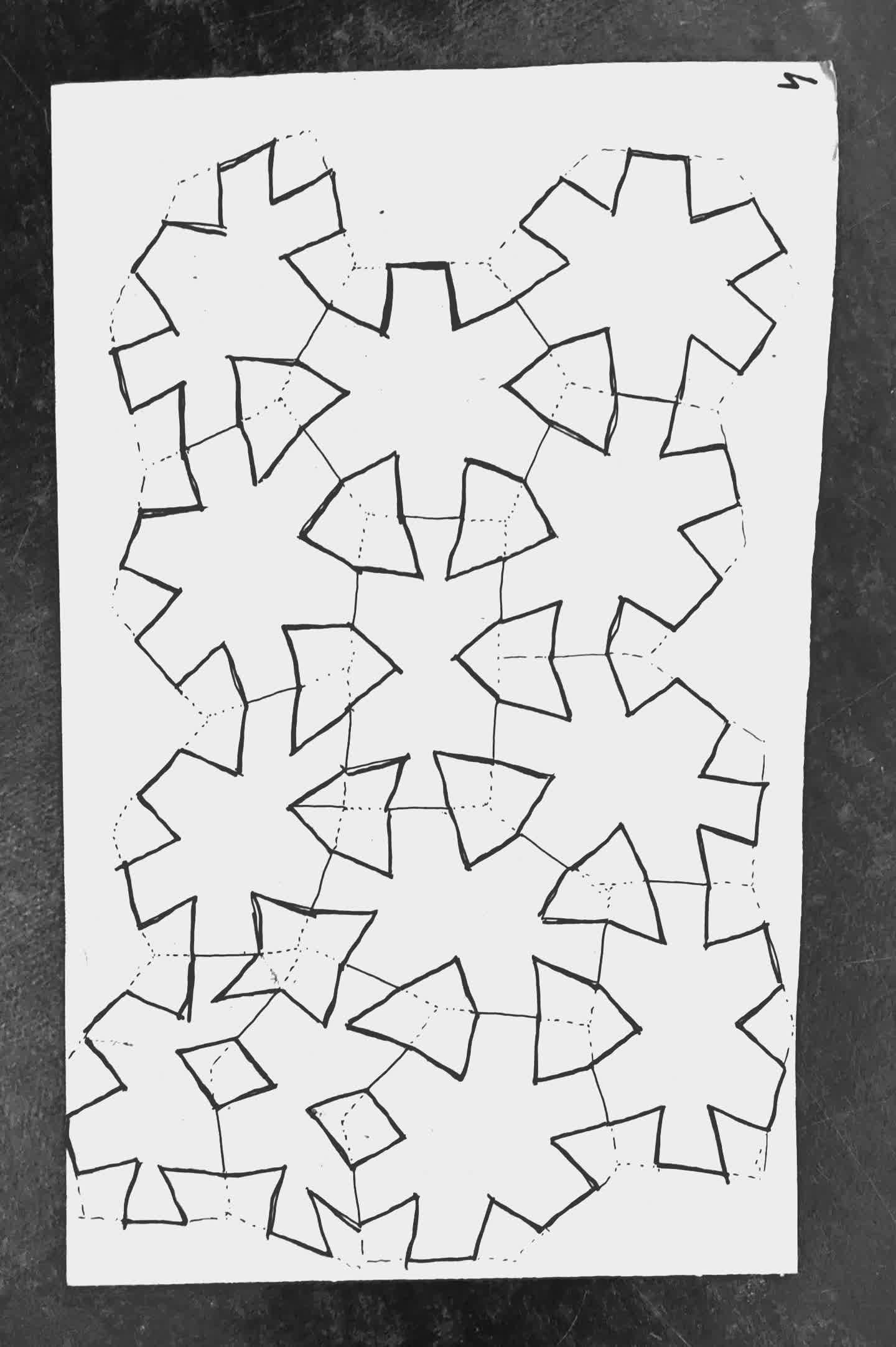

In the industry, molds are widely used as a means of reproducing a designed shape. For logistical reasons, when manufacturing a mass-market item, two prints from the same mold must be absolutely identical. This raises the question of the reproducibility of a molded object when (literally) suppleness is introduced into a mold. The idea of a soft mold immediately evokes the impossibility of perfect reproduction and, by extension, the appearance of non-drawn shapes. This raises the question of what the designer draws and what he leaves to chaos.

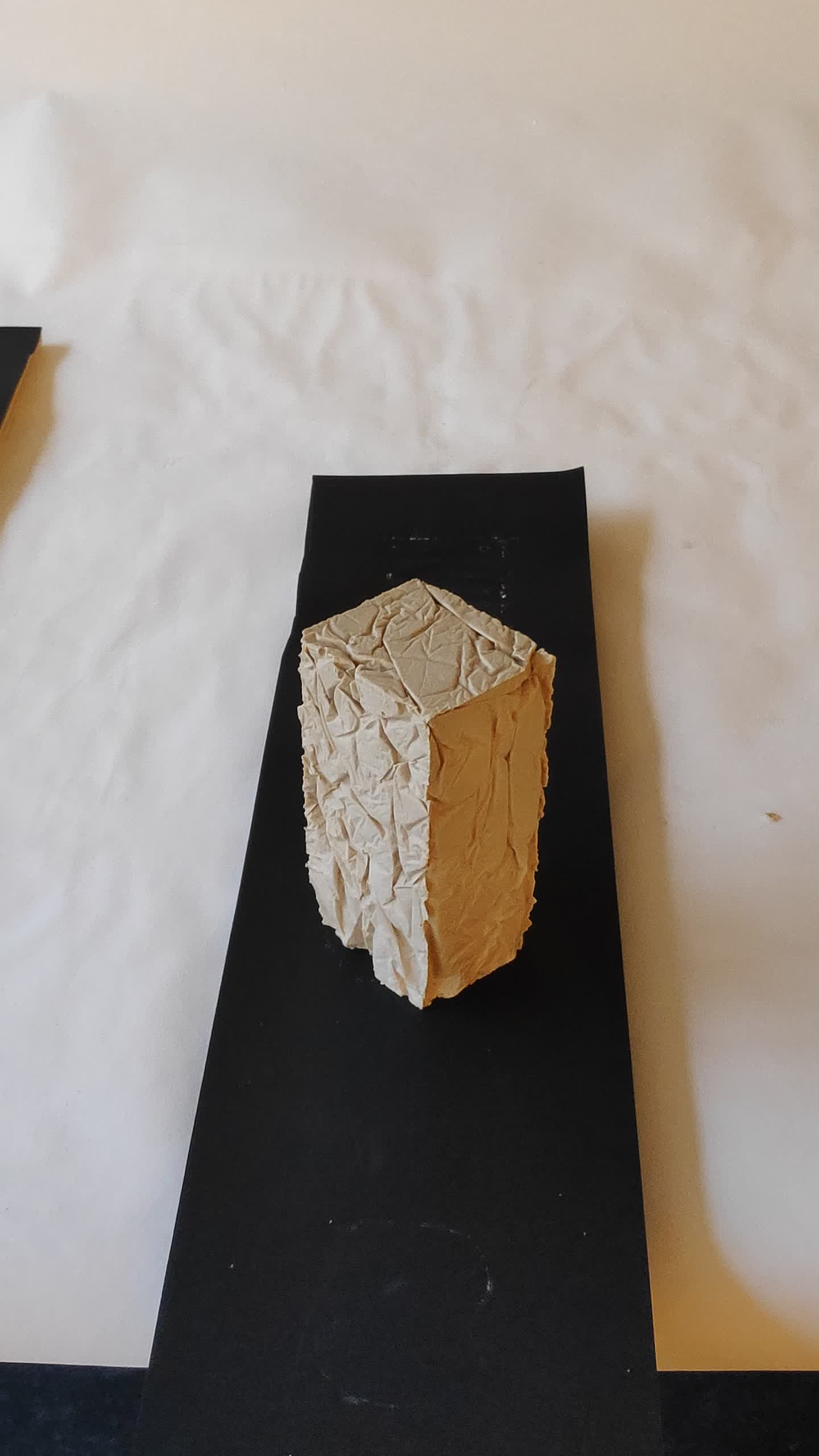

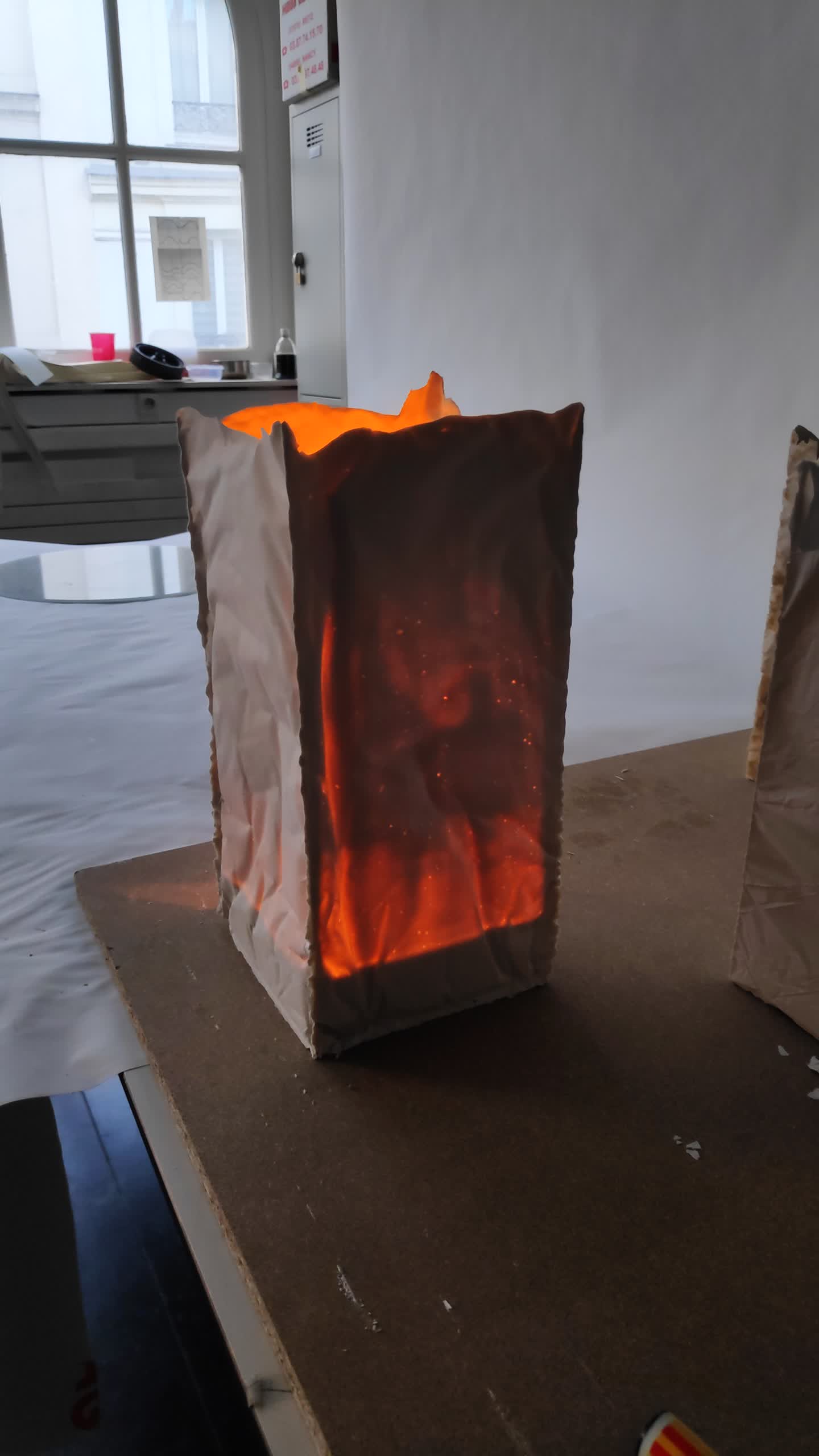

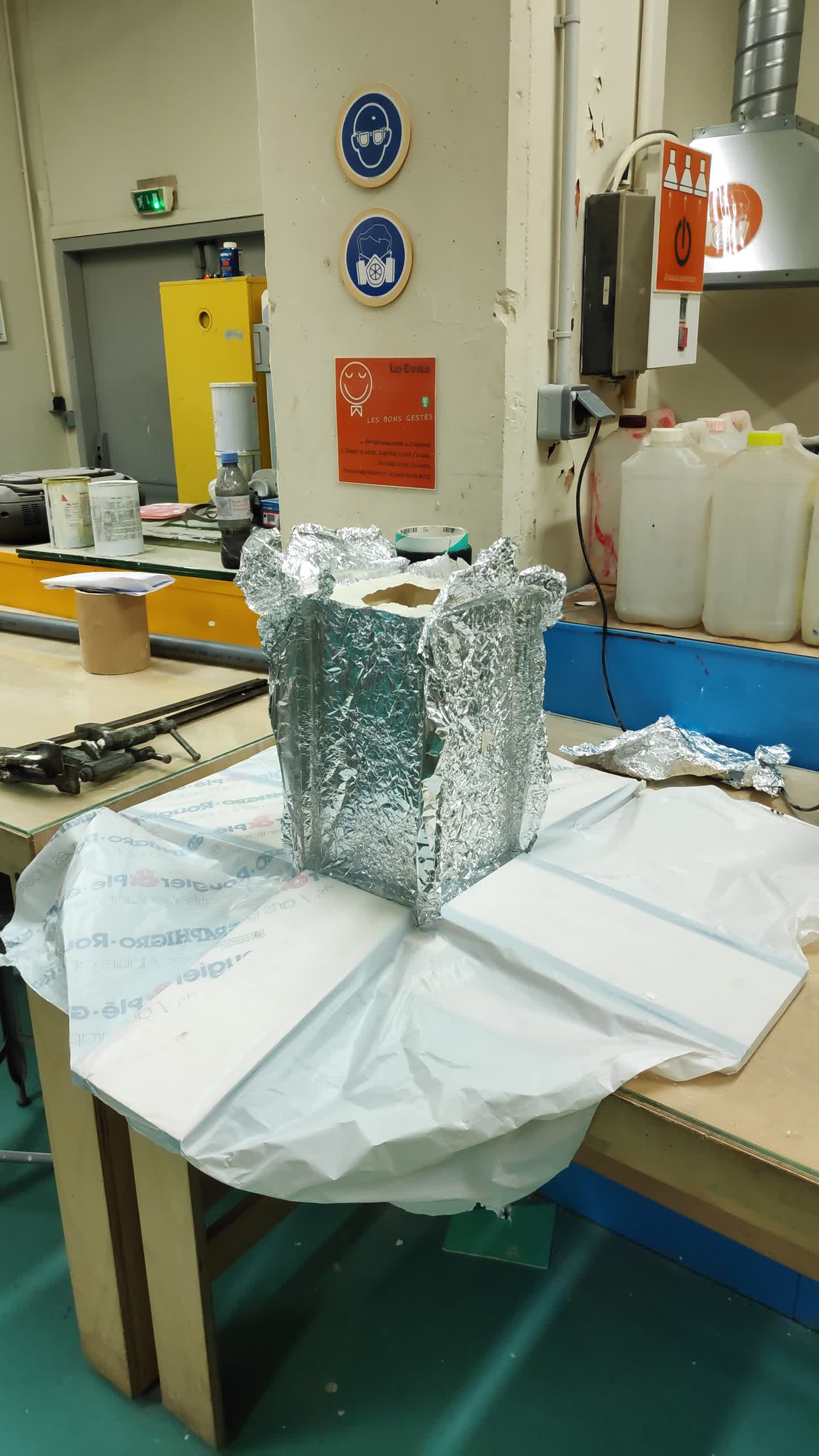

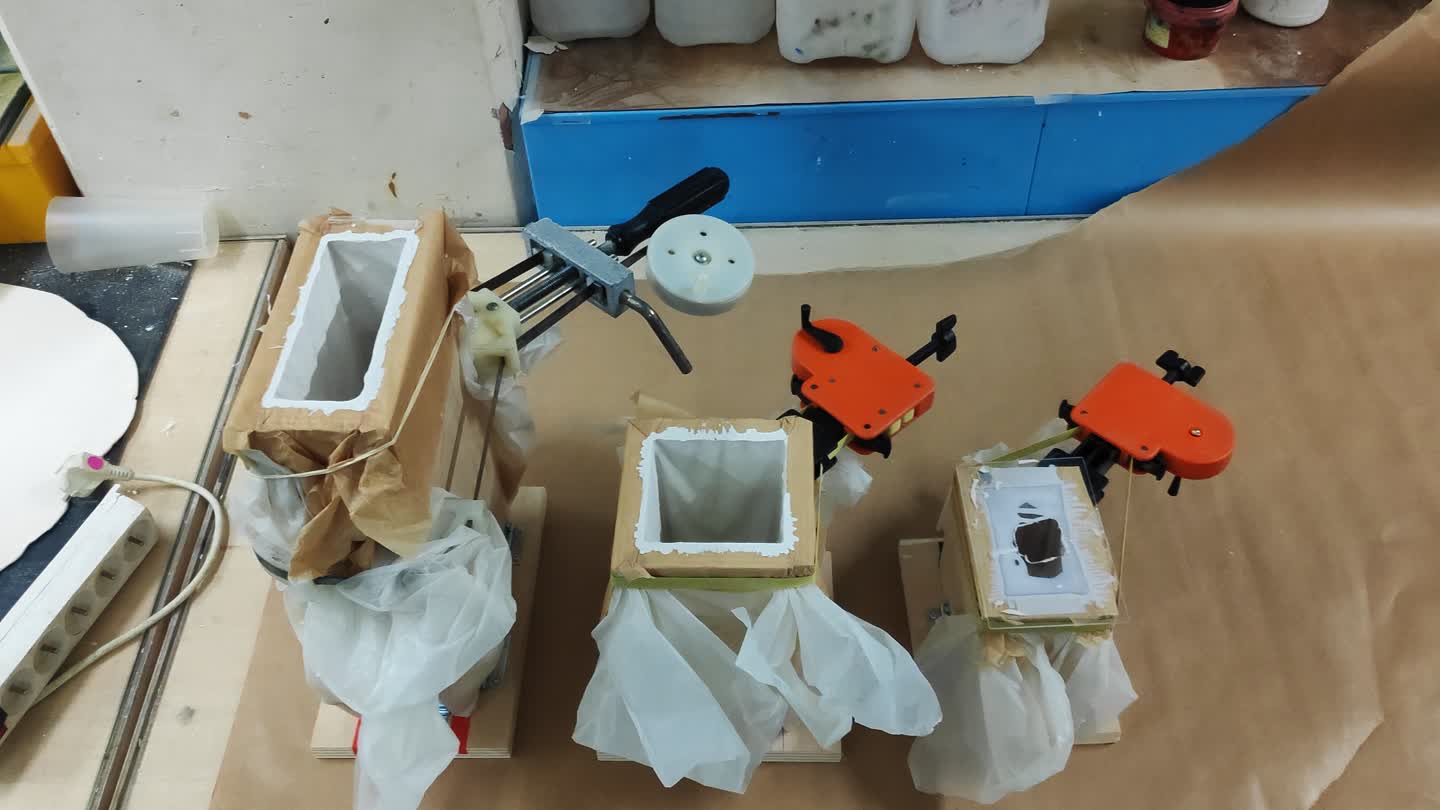

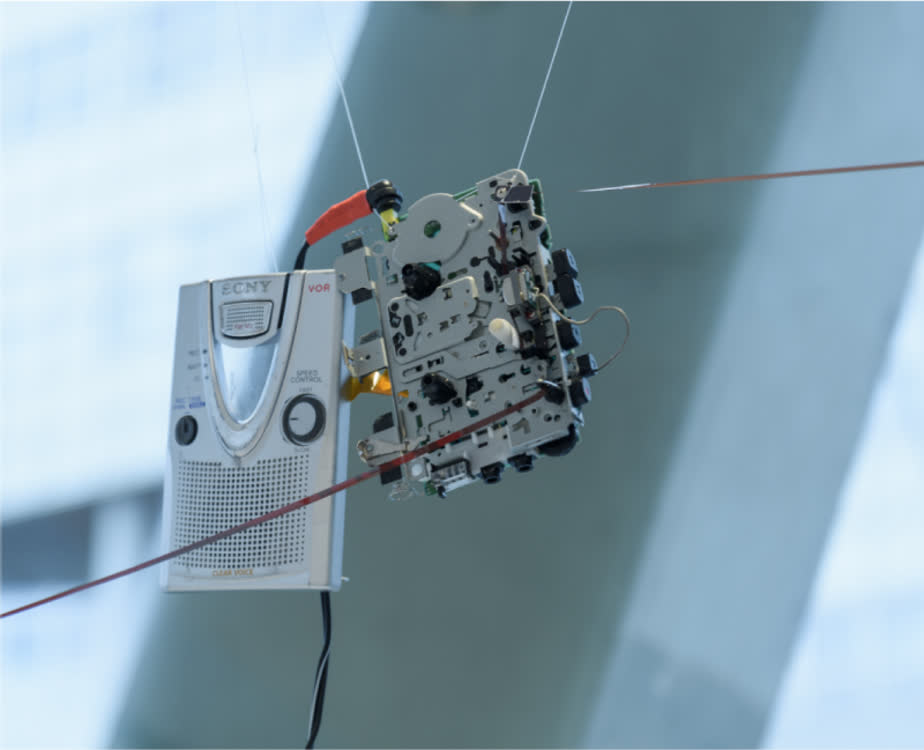

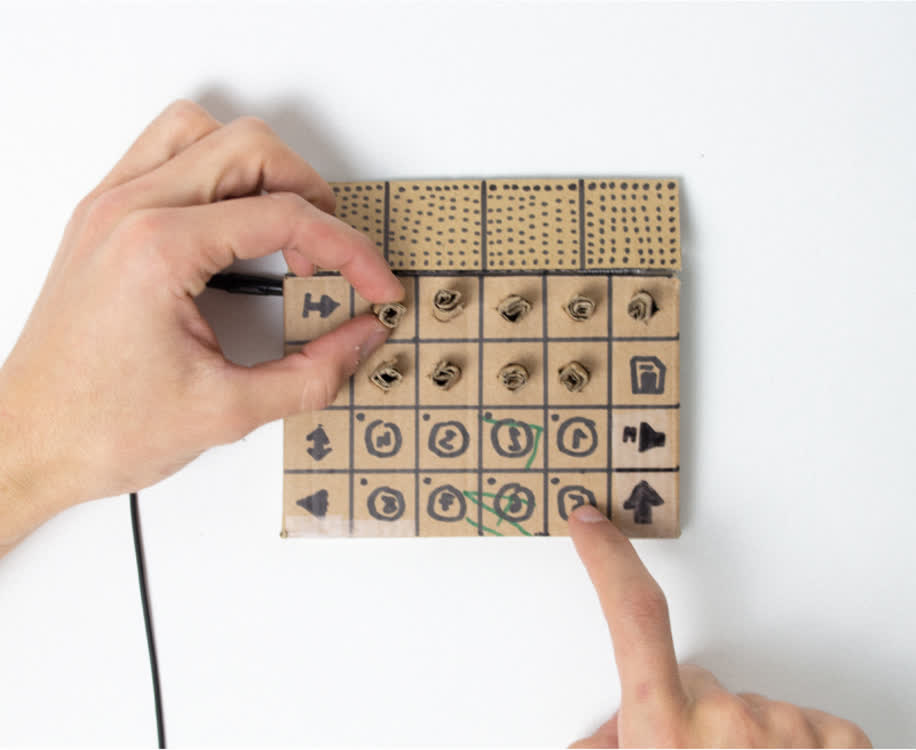

I began the project by experimenting with molding the plaster in all kinds of paper: classic paper, plastic sheeting, aluminum foil, baking paper, etc. These tests, which were simply plastic experiments without any drawing, enabled me to understand how the plaster behaved in contact with these papers. However, I leave everything to chance and have very little control over the final shape. From then on, I wanted to ask myself what role randomness could play in the creative process: where to place the cursor between chaos and drawing.

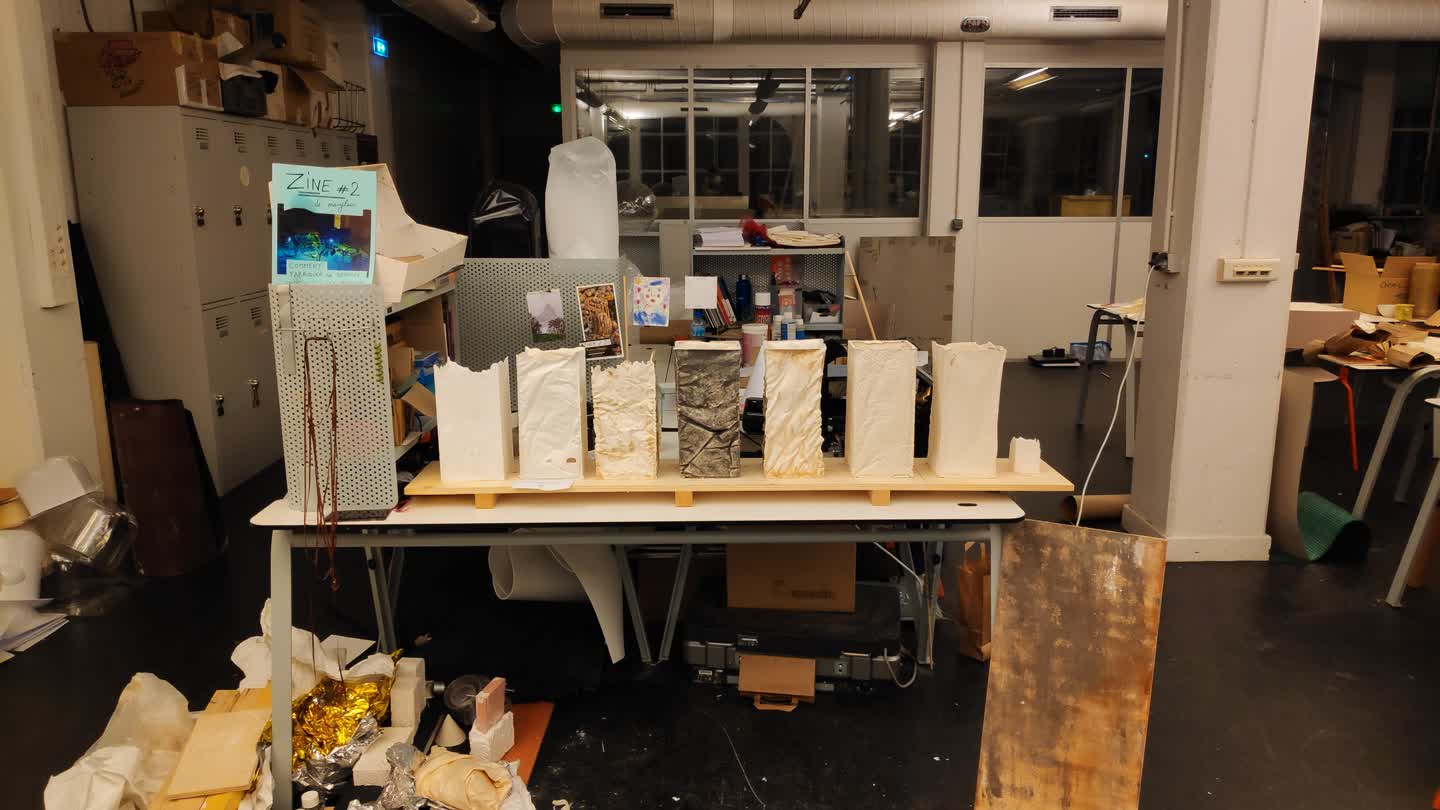

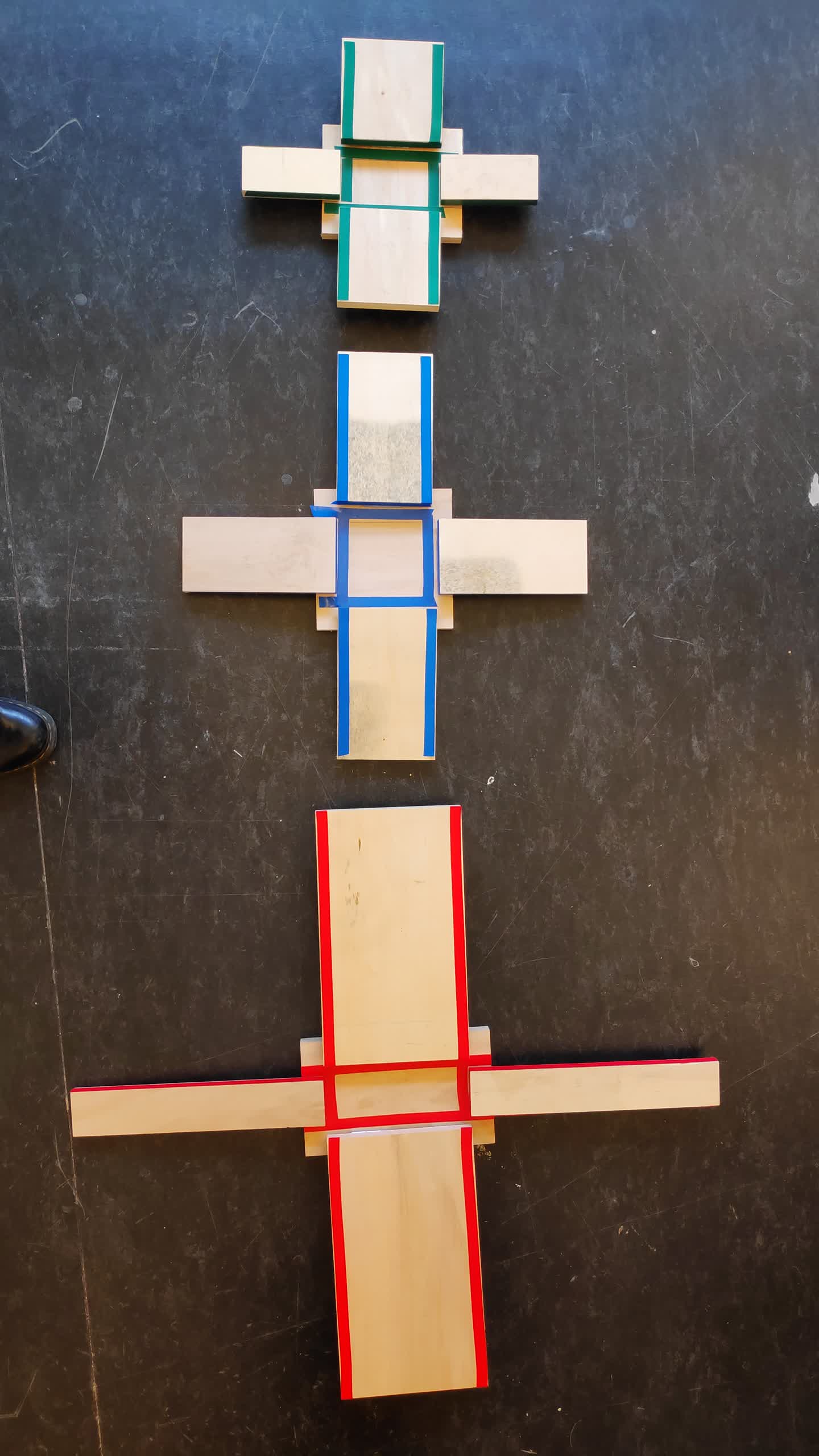

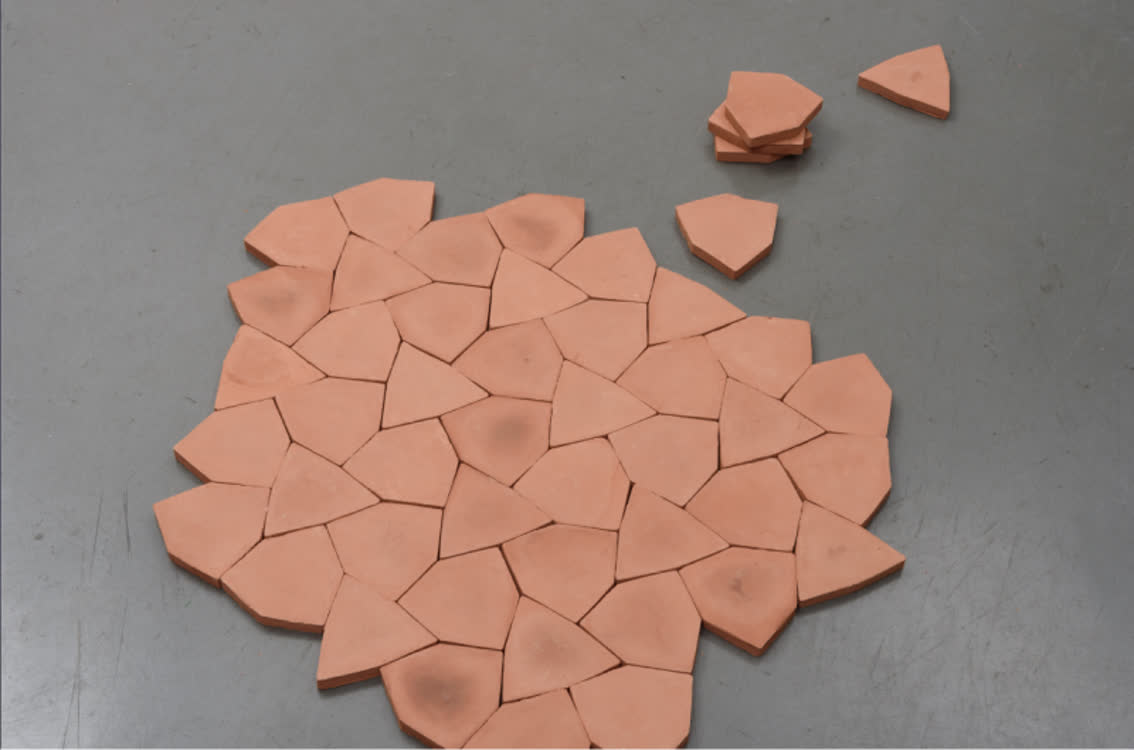

I began to take an interest in developing a manufacturing process that would enable me to define a general shape for the object, while retaining an uncontrollable but well-defined element of randomness. Once the protocol and the matrix had been perfected, the production process gained in speed, reaching up to 4 prints per day, but also in meaning as well. It is through the multiplication of these prints that their individual uniqueness is revealed and the project becomes interesting. After several prints, I adapted the matrix into three formats to create an assembleable range.

This project was made at ENSCI—Les Ateliers under the direction of Jean-François Dingjian and François Lafortune.